Rambaudi High Speed

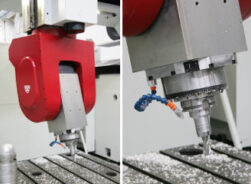

RC : 5-axis High Speed Machining Centre – Gantry type

The high speed machining centre RC are the result of a long and extensive experience that the company has achieved in the production of gantry type machines. Tmachines of the RC lines are especially designed for semi-finishing and inishing operations on steel mould and cast iron dies and for a complete machining of aluminium alloy parts for both the aeronautical and mould and die industry.Its specific accessories make it particularly suitable for resin, graphite and carbon fibre machining.

The RC line is characterized by:

• removal capacity starting from 9 m³

• dynamics independent from the workpiece mass

• working head designed for high stock removal and high speed

• structures well dimensioned for high static and dynamic loads

• removal capacity on steel >200 cm3/min, on aluminium > 3000cm3/min

• max. speed of each axes = 40 m/min

• load capacity on the worktable 10t/m2

• easy loading and clamping of the pieces

• optimal vibration damping

• high positioning accuracy

• completeness of equipment and accessories

• simple maintenance

Structural stiffness

Structural stiffness The bases and the column are widely dimensioned to support high cutting forces and for an optimal

vibrations damping.

High removal capacity and high-speed machining

The Glob 89 G and Glob 123 G milling heads have been designed to obtain :

- High penetration into the cavities

- Max approach to the piece

- High A axis strokes for undercuts machining

- Absenceb of maintenance of kinematics

- Easy maintenance

- Use of dimensioned spindles to grant the maximum reliability.

High rigidity and accuracy

Ram with section 400x400mm

-Z guides positioned at the center of the side surfaces to minimize the effects of the change of the temperature and to have a more symmetric reaction to the forces in the main directions

-Strong C type Y slide to position the Z axis roller bearings in the center of the side surfaces of the ram.

Kinematic of the linear axis

High stiffness and accuracy X-axis: - 2 guides size 55 (up to 4 +5 roller bearings) for each side - 2 Heidenhain optical scales Y-axis: -2 guides 65 (3 +2 roller bearing) -1 Heidehain optical scale Z axis: 2 guides size 55 (3 + 3 roller bearing) 1 Heidenhain optical scale

Cinematic of the linear axis

X gantry axis - rotating ball screws grease lubricated for X 2200, 3000 , 4000mm - Racks and pinions with dual drive technology for X= >6000mm Y and Z axes Rotating ballscrews grease lubricated.

Copyright 2019 DCA Dimensional Control